To study the detonation waves produced by explosives, the Ordinance Division at Los Alamos was using high current X-ray machines capable of pulsing as fast as every ten millionth of a second. Studying the explosive compression of a solid metal core as it was compressed to less than half its original volume was possible by setting the explosions in a magnetic field. Wires placed within the cores also supplied information as the cores compressed.

Radioactive lanthanum inserted into the cores also provided an intense source of gamma radiation which could be studied as the core compressed. An early computer from IBM helped with mathematical analysis.

An implosion lens system designed by John von Neumann and Edward Teller calculated that solid 239-Pu94 would be compressed by even higher pressures than those yet attempted, so that a hollow core would be unnecessary. A sub-critical mass would detonate when compressed sufficiently. A solid sphere of plutonium should work.

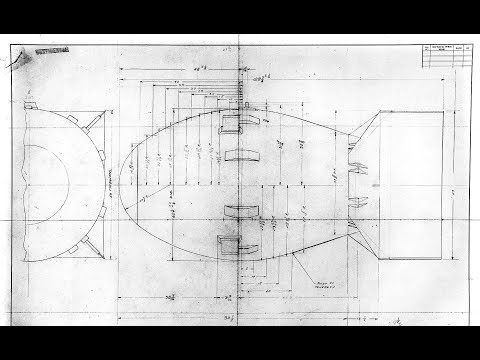

The final design used truncated pyramidal blocks of two different explosives, a faster burning outer layer and a slower burning inner layer pointed at the core, all on the outside of a heavy natural uranium, spherical tamper (neutron reflector). Slight irregularities in the spherical shock waves were smoothed out by the tamper as it was compressed onto the plutonium core.

By December 1944, George Kistiakowsky's team had a promising design But they were not certain that the bomb's effect would be greater than 500 ton of TNT. Kistiakowsky decided to machine the cast blocks of explosives for further precision, a daunting task with about a hundred pieces (made with a precision of a few thousandths of an inch) that had to form a five foot diameter hollow sphere.

Making the moulds and casting the explosives was also difficult. The composite was poured as a slurry of hot wax, molten TNT and RDX a powder more powerful than TNT alone. The slower burning composite was poured as a slurry of barium nitrate, aluminum powder, TNT, stearoxyacetic acid and nitrocellulose. These cast blocks, each weighing about 50 pound, had to be painstakingly cooled to prevent the ingredients separating or the formation of bubbles that would ruin the explosive effect.

Testing meant 50,000 machining operations and exploding more than 20,000 castings . . . without a single accident.

Oppenheimer decided to freeze the design on March 4th 1945.

In July 1945, at Los Alamos, Kistiakowsky's team struggled to complete the precision explosive castings to complete the first 239-Putonium bomb. When this was assembled, the castings forming a five foot sphere surrounding a spherical natural uranium (mostly U238) tamper to reflect neutrons escaping the core.

When this was assembled, forming a five foot sphere, the hollow spherical natural uranium tamper was inserted through a gap in the explosives.

The two small hemispheres of plutonium (nickel plated to stop stray alpha particles) were not very radioactive. Technicians carefully placed the polonium/beryllium initiator between the hemispheres and put the assembled core through a hole in the heavy uranium tamper. There were a few anxious minutes as the uranium plug was slid into the hole and the remaining explosive castings fitted into place over it.

YOU ARE READING

Nuclear

Non-FictionH.Becquerel found uranium emitted radiation and, in1898, M.Curie extracted minute traces of radium from ore. J.Maxwell predicted electro-magnetic radiation in 1855 and Einstein formulated special relativity; mass could be converted into energy. In...